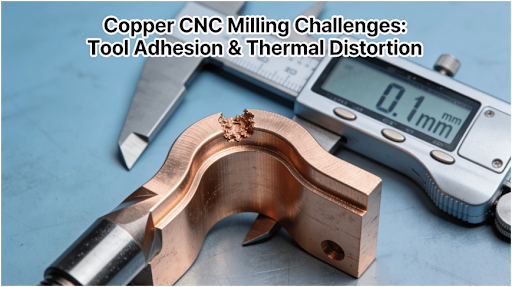

l File name Figure 1:copper-cnc-machining-challenges.jpg

Introduction

For sectors like aerospace, medical, and electronics, copper alloysare of immense importance because of their superior electrical and thermal properties. But due to the use of conventional CNC milling processes, various difficulties have been encountered, such as tool adhesion, thermal distortion beyond 0.1mm, and material waste of up to 12%. These difficulties have led to significant delays and cost escalation in projects. The primary reason for these difficulties has been identified as the special properties of copper materials, which have high ductility and thermal conductivity. But due to the use of conventional CNC milling processes, which are not optimized for these materials, this process has remained inefficient and ineffective.

This article seeks to discuss the various ways through which advanced precision engineering techniquesand sophisticated manufacturing techniques, including 5-axis machining and thermal management, offer a complete solution to the challenges associated with efficient machining of copper materials. By following strict quality foundations as set out in the ISO 9001quality management systems, precision outcomes, substantial cost savings, and optimized supply chain benefits can be achieved. The following sections of this article will discuss the major techniques used to master efficient machining of copper materials.

What Are the Primary Challenges in Copper Alloy Machining?

Copper alloy machining is beset with challenges, and understanding them is the first step to finding solutions to them.

l Tool Adhesion and Rapid Tool Wear: High ductility and thermal conductivity of pure copper like C11000result in bonding between the material and the cutting edge of the cutting tool. Thus formed is a built, up edge (BUE)which shortens the tool life by as much as 60%. This is the reason why cutting tools just rub against the material rather than cut it. In this way, the surface finish is poor and the cutting tool also wears out at the flank.

l Thermal Distortion and Dimensional Instability:Thermal managementis one of the most important factors in machining. Lack of thermal management results in a situation where the material expanses in an uneven manner. Thin materials are especially sensitive to this problem because they bend. Therefore, it is very hard to achieve tight tolerances, and such materials have to be scrapped. Problems of heat treatment of beryllium copper (a copper alloy)arise because the material undergoes a state of stress after heat treatment.Consequently, maintaining tolerances lower than 0. 02mm becomes hugely challenging.

l Surface Finish Inconsistencies and High Scrap Rates: A fine surface finish is hard to achieve. In the absence of optimal values, the surface finish may be as rough as Ra 3.2, which does not meet the requirements for parts such as electrical contacts and RF shields. These problems, coupled with deformation, lead to a scrap rate of over 12%. The inefficiency highlights the importance of standardized procedures, as suggested by the need for measurement science, as advocated by bodies such as the National Institute of Standards and Technology (NIST), in manufacturing.

How Can Precision Engineering Techniques Enhance Copper CNC Milling Accuracy?

Precision engineering techniques make copper machining a straightforward process.Through copper CNC milling services, businesses can achieve higher precision.

l File name Figure 2:5axis-copper-machining-solution.jpg

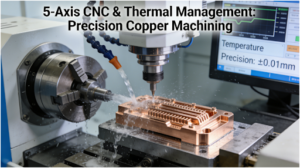

1. Advanced 5-Axis CNC Machining for Complex Geometries

The dynamic tool orientation of 5-axis CNC machiningallows the tool to reach the workpiece from any desired direction. This ensures single-setup machining, eliminating the accumulation of errors as in traditional 3-axis CNC machining systems where repositioning of the part is required. This technique is particularly useful for complex geometries with deep cavities and undercuts, allowing for tighter tolerances as close as ±0.01 mm to ±0.05 mm. This technique is in full compliance with the very strict geometric dimensioning and tolerancing rules as outlined in the ASME Y14.5standard.

2. Adaptive Toolpaths and Strategic Parameter Optimization

Intelligent CAM software optimizes toolpaths with a constant chip load and optimal tool engagement. In machining difficult materials such as pure copper, high-speed cutting with moderate feed rates under Minimum Quantity Lubrication (MQL)conditions is required to manage heat generation and tool adhesion. In contrast, a segmented cutting technique with stronger tools with a coating such as AlTiNis required for hard materials such as beryllium copper, where high cutting forces are encountered. This technique can improve efficiency by 50%.

3. Proactive Thermal and Distortion Management

Machining environment controlis essential for precision. Installation of high-pressure coolant systems (≥7 MPa) focused on the cutting interface efficiently removes heat, maintaining a stable workpiece temperature. In precision applications, such as thin-walled motor end cap machining, cryogenic machining with liquid nitrogen jetscan be considered. This sophisticated thermal management technique eliminates thermal expansion, maintaining flatness values within 0.015mm and raising part acceptance to over 99%.

What Strategies Drive Cost-Effective Production in Copper Machining?

The production process in copper machining requires a strategic approach to cost-effective production, focusing on the significant cost drivers: materials, tools, and time.

1. Material Optimization and Waste Reduction

Material costs can be anywhere from 45% to 60%of the total project cost. Blank sizingand advanced nesting software ensure maximum efficiency in the use of all the raw materials, reducing waste to a significant extent. Furthermore, selecting the appropriate copper type for the project, balancing the required properties with the cost, helps avoid over-engineering and unnecessary spending.

2. Tooling Life Extension and Process Consolidation

The cost associated with tooling and consumables ranges between 15-25%. The application of specialized tool geometries and coatings that are optimized for copper alloys can increase tool longevity by 50-80%. When paired with single-setup 5-axis machining, multiple custom fixtures are eliminated and part handling is reduced. This process consolidationcan reduce overall project costs by 30-45%.

3. Data-Driven Production and Value Engineering

The application of a database of past machining parameter optimizationallows for exact cycle time prediction and optimization from the start, reducing trial and error. This value engineering process, paired with a structure for continuous improvement similar to that used in ISO 14001environmental management systems, ensures that processes are not only cost-effective but also sustainable.

How Does Industrial Innovation in CNC Technology Improve Custom Copper Parts?

Technological innovation is the key that has enabled the custom copper parts industry to reach for greater capabilities and reliability.

- Generative Design and Topology Optimization: Technological innovation in software has enabled the creation of highly efficient and lightweightcustom parts that, prior to this technology, were impossible to produce. Generative designemploys algorithms that suggest optimal material distribution according to the desired loads. This enables the creation of complex and organic parts that can be produced with certainty using 5-axis CNC milling machines, pushing the limits of custom parts manufacturing to new heights.

- Integrated Real-Time Monitoring and Closed-Loop Control: The use of intelligent technologies in the production of custom parts has made it possible for a CNC machine to have sensors that can detect spindle loads, vibration, and temperaturecontinuously. This information is operated by a closed, loop control mechanismcapable of changing feed rates automatically for achieving the best results or alerting the operator about the tool wear that is going to happen literally minutes before it happens. It is a crucial factor for custom parts on a mission.

- Digital Thread and Seamless Prototype to Production: It is also the integration of the workflow that is visible here. Therefore, a digital threadthat links CAD, CAM, and production exists. This guarantees that the transition from the virtual to the physical world will be without any hiccups.Therefore, a smooth transition between a copper prototype machiningvalidation run and production represents a major competitive edge of a company operating in a constantly changing market.

What Are the Key Considerations for Selecting a Reliable CNC Copper Machining Supplier?

It is very important to assess a supplier. However, this is a bit involved and requires consideration beyond just a quote.

1. Verification of Technical Capabilities and Certifications

It is important to note that a supplier’s technical capability, including their problem-solving abilities, should be verified. A site audit, including a live demo such as machining a thin-walled copper part, is important in verifying the supplier’s capability for distortion control. However, it is important to note that certifications such as ISO 9001, IATF 16949, and AS9100Dare not only a supplier’s qualifications but are also a gauge of their quality management system. These are a “must-have” for a supplier.

2. Assessment of Specialized Tooling and Material Expertise

A trustworthy supplier is expected to have a tooling library, which is basically a collection of tools for copper alloys based on their shape and types of coatings. This will allow them to get the settings right from the beginning, thereby neither causing delays nor compromising the quality. Besides that, they ought to offer a complete range of metal CNC milling servicesfor different materials.

3. Review of Documented Case Studies and Problem-Solving Expertise

There is nothing like past performanceis the best predictor of success in the future. The supplier should be asked to share with you case studiesof their work. This will confirm that they have the right expertise to handle the issues most commonly encountered such as achieving thermal distortion control or to deliver surface finishes down to the microscopic scale. Understanding how your supplier tackles problems will also give you confidence that they are a dependable copper milling supplier.

How to Optimize the Supply Chain with Custom Fabrication in Copper Projects?

Custom fabrication is an effective method for optimizing the supply chainand goes beyond just manufacturing parts. It involves providing integrated solutions that improve efficiency and reduce costs.

1. Design for Manufacturability (DFM) and Part Consolidation

Involving suppliers in DFM analysisis vital for projects. Suppliers can advise on modifications that improve manufacturing costs and efficiency. One method for optimizing the supply chain is part consolidation. In this method, an assembly consisting of multiple parts is converted into one complex part that can be machined in one operation. This method eliminates assembly costs and potential failure points.

2. Turnkey Solutions and Reduced Administrative Overhead

Working with a supplier that offers turnkey solutions—i.e., solutions that include everything from material and machining to post-processing operations like plating and polishing—can greatly reduce administrative costs and improve overall efficiency. In turnkey solutions, the number of suppliers that need to be managed is reduced. This greatly improves efficiency and reduces costs.

3. Agile Production Planning and Lead Time Reduction

An optimized supply chain is an agile supply chain. Data-based production planning can be used for effective lead time forecasting and scheduling. Production planning techniques, such as optimal batch sizes, can be used for achieving a balance between inventory costs and production efficiency. Optimizing the entire process from a copper parts quotefor a custom fabrication partner can reduce overall project cycle times by as much as 40%, providing much-needed competitiveness for a company.

Conclusion

The challenges of copper alloy machining are significant, yet entirely surmountable. The use of precision engineering techniques, such as 5-axis machining and thermal management, can produce accuracy that rivals the best, reducing scrap rates to near zero, and opening new possibilities for designers and manufacturers. Strategic cost control and a disciplined approach to finding a qualified supplier can ensure that these advanced techniques are used not only to produce parts, but to optimize a supply chain, saving a company 30% or moreand giving them a commanding competitive advantage in today’s market.

FAQs

Q: What is the least tolerance which can be achieved in copper CNC milling?

A:Precision copper milling can achieve tolerances as small as ±0.01mmwith advanced 5-axis technology, which is highly accurate for aerospace parts and similar components. However, there are some factors which might influence this, but with certified copper milling, precision is guaranteed.

Q: How do I lower the costs of custom parts from copper machining?

A:Three ways to reduce costs: using less raw material, choosing the most efficient tool paths, and batch production. According to research, these actions would reduce costs by 30, 45%, and quality can be maintained through ISO, compliant practices.

Q: What are some of the certifications which one should look for in copper milling suppliers?

A:The copper milling service provider one is working with should be certified with ISO 9001for quality management system standards, IATF 16949for automotive industry quality management system standards, and AS 9100Dfor aerospace industry quality management system standards.

Q: What are the differences in machining copper alloys when compared to other metals?

A:Machining copper alloys are known for being difficult to machine. This is due to the fact that copper alloys have high thermal conductivity and stickiness. This means that special toolsshould be used when machining copper alloys. The parameters for machining copper alloys and steel materials are different.

Q: What file types are accepted for a quote on a copper part?

A:The file types accepted include STEP, STL, and IGES. This way, one is able to get a quote on the part he/she needs within 24 hours.

Author Bio

The writer of this piece is a precision manufacturing specialistat LS Manufacturing, a firm that helps engineers and researchers solve difficult component challenges in aerospace, medical, and electronic fields. Through their certifications like ISO 9001, IATF 16949, and AS9100D, they bring quality solutions for complex challenges by leveraging the latest technology.For more information or to arrange a no, obligation project review, visit their Copper CNC Milling Servicespage or get in touch with them today to turn your idea into a cost, effective reality.